Best Practices for Electrical Sub-Panel Installation

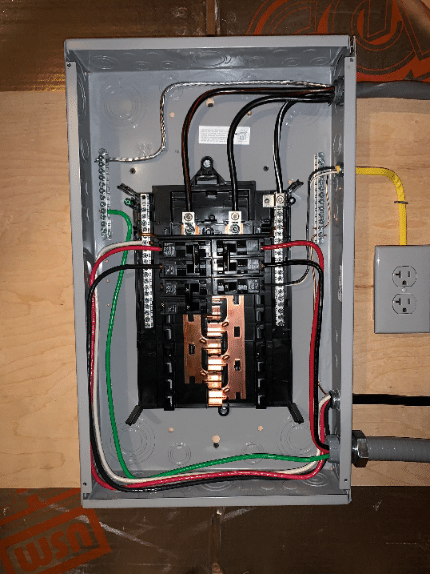

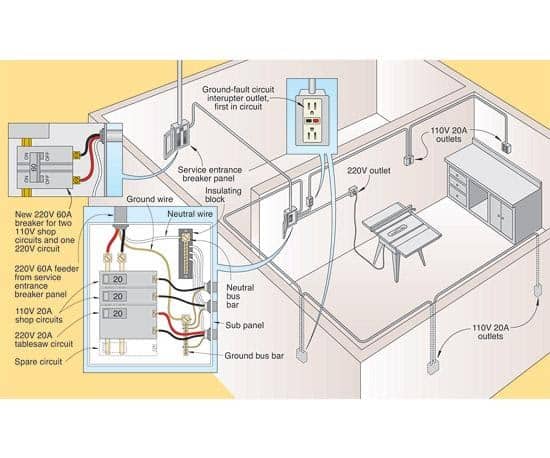

Electrical sub-panel installation by a licensed electrical professional is critical for the safety of your home. By definition, best practices are professional procedures, methods or techniques that have been generally accepted or prescribed as being superior, or more effective, to those achieved by other means. When installing new equipment, especially electrical panels, the NEC (National Electric Code) prescribes the standards to meet in order to achieve minimum safety. Best practices go beyond minimum codes to further minimize hazards while achieving optimal performance. The use of an MB (Main Breaker) panelboard versus an MLO (Main Lug Only) panel, even when not required, provides convenience to the homeowner.  In the event maintenance or repairs were necessary inside the sub-panel, power could be disconnected at the sub-panel, for a single electrical zone in the home. Additionally, this saves a trip up and down stairs or traversing a long distance across the home to disconnect power to the electrical main panel. From a wire efficiency and cost perspective, optimal placement of the sub-panel should be approximately two-thirds of the way between the main electrical circuit breaker panel and the longest branch circuit. Such placement minimizes individual branch circuit wire lengths. By reducing multiple branch circuit wire lengths reduces both labor and material costs. Finally, looping the feeder wire at the top of a sub-panel removes the strain from feeder conductors and terminals, and provides some additional wire in the event future work or modifications must be performed.

In the event maintenance or repairs were necessary inside the sub-panel, power could be disconnected at the sub-panel, for a single electrical zone in the home. Additionally, this saves a trip up and down stairs or traversing a long distance across the home to disconnect power to the electrical main panel. From a wire efficiency and cost perspective, optimal placement of the sub-panel should be approximately two-thirds of the way between the main electrical circuit breaker panel and the longest branch circuit. Such placement minimizes individual branch circuit wire lengths. By reducing multiple branch circuit wire lengths reduces both labor and material costs. Finally, looping the feeder wire at the top of a sub-panel removes the strain from feeder conductors and terminals, and provides some additional wire in the event future work or modifications must be performed.

Electrical Sub-Panel Requirements and the National Electric Code

Major electrical additions, extensions or modifications such as adding a new electrical sub-panel require an electrical permit in order to legally perform the work. To obtain a permit, a qualified person, usually a master electrician, must submit a description of the work to the AHJ (Authority Having Jurisdiction). The AHJ is usually found in a city’s code department or county planning and zoning. Once the electrical sub-panel installation is complete an inspector assesses the work based on meeting requirements in the NEC. It is recommended to hire a licensed and experienced expert when choosing to install an electrical sub-panel.

According to NEC 250.32(B)(1), all sub-panels require separate neutral and equipment grounding termination bars. These bars must be separated in order to isolate the grounded conductors’ “neutrals” from the equipment grounding conductors and metal cabinet. Generally, isolation is accomplished with a factory installed plastic spacer located under the neutral bar.

Unlike electrical main circuit breaker panels supplied with only three conductors, the feeder wires supplying an electrical sub-panel must contain four conductors. The feeder wire will be a multi-wire 240-volt circuit consisting of two ungrounded conductors’ “hots” usually black and red in color, one grounded conductor “neutral” indicated by a white sheath, and a separate equipment grounding conductor generally identified as a bare copper conductor or green sheathed wire. The reason for this goes back to the electrical sub-panel requirement for a floating neutral as described above. All equipment grounds must terminate on a ground bar and must travel back to the electrical main panel. The most common type of feeder wire is single conductor THHN or THWN.

NEC 225.30, 31, and 33 combined, effectively require a MB type panel where the electrical sub-panel is located in a separate or detached building, or if the sub-panel consists of more than six circuit breakers. The rationale for this requirement is to facilitate maintenance or emergency power shut-down at the detached building versus requiring a person to disconnect power back at the main building.

Separate Building Installation

Where an electrical sub-panel is installed in a separate building such as a detached garage, shop or other structure, NEC 225.32 requires the sub-panel be installed at a readily accessible location near the point where the feeder conductors enter the detached building. The sub-panel can be located either inside or outside the building as long as the cabinet is appropriately NEMA (National Electrical Manufacturers Association) rated for the conditions of exposure. Exterior conditions of exposure could be damp or wet locations as defined by NEC 100.

Finally, for electrical sub-panels installed in separate buildings, NEC 250.32(A) requires the equipment grounding bar to be bonded to a separate GEC (Grounding Electrode Conductor), further connected to one or more grounding electrodes. The most common grounding electrodes for residences are one or more ground rods depending on a successful ground resistance test. The exception for the grounding electrode requirements is when a single branch circuit or multi-wire feeder circuit supplies power to a detached building.

Home Performance Group Electrical Sub-Panel Installation in Kansas City

An electrical sub-panel can be one of the most critical elements in a home’s electrical system. A safe sub-panel and quality code compliant installation are paramount to protecting people and their home. Consider hiring a licensed electrical expert with specialized knowledge in residential panelboard installations. An investment with a reputable and experienced company can save tens of thousands of dollars in fire damage, and most importantly lives.

At Home Performance Group, we continue to invest in technical electrical training so we can safely install and upgrade electrical sub-panels. We have performed numerous service upgrades, main panel replacements, and sub-panel installations for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 22 November 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |