Improve Your Comfort Through Better Ductwork

A NIST (National Institute of Standards and Technology) study on energy loss through ductwork found in many cases over 50 percent of heating and cooling created by a furnace or air-conditioner can be wasted due to ductwork air leakage and lack of insulation. Additionally, leaky ductwork poses health and safety concerns by allowing particulates, microbes, and other gases into the breathable air stream. If the duct system is installed through an unconditioned attic, basement, or crawlspace, the risks are even higher, and comfort issues worse.

How Comfort is Lost Through Ductwork Problems

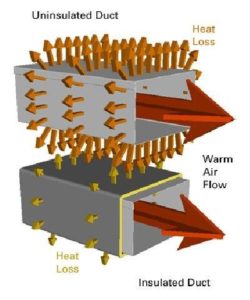

There are two primary ways energy and correspondingly comfort is unintentionally lost through a poorly constructed ductwork system.

Air leakage through unsealed joints, seams, holes and connections in the duct walls. Building science and physics demonstrates air moves from a location of higher pressure to lower pressure. When turned on, the indoor fan creates higher pressure inside the ductwork allowing the heating and cooling system to move air throughout the home. When duct leaks are concentrated on the supply side of the heating and cooling system, cool dry conditioned air will be lost to the attic. The loss of conditioned air may result in inadequate airflow to rooms and significant comfort areas in the home. If the leaks are concentrated on the return side, hot humid untreated air is pulled into the return duct, and this will exacerbate the comfort in the home.

Code Requirements and Best Practice

5 Benefits of Sealing and Insulating Ductwork

- Improved thermal comfort in delivering maximum conditioned airflow to the space without unwanted humidity and heat.

- Protected health and enhanced safety by sealing out harmful gases, particulates or contaminates from entering the delivered airstream.

- Superior heating and cooling equipment efficiency. Preventing heat losses and added humidity loads to the home, HVAC equipment can work efficiently by providing the correct amount of heat or coolth based on the home’s load.

- Potentially smaller-sized HVAC equipment. In existing homes, the heating and cooling equipment may have been artificially increased in size to accommodate or offset the unintended loads added to the home by poor ductwork. When correcting duct issues such as sealing and insulation, the duct system effectively delivers the correct amount of conditioned air, at the correct temperature without unwanted added loads the HVAC system may be able to be reduced in size in accordance with a Manual J heating and cooling load calculation. This may result in thousands of dollars of savings on equipment you do not need, as well as lower operating costs and future replacement costs as well.

- Lower monthly utilities. The PNNL (Pacific Northwest National Laboratory) conducted an analysis on the monthly energy savings that can be realized by sealing ductwork and adding insulation. The report found with a typical home could save up to $133 per month.

Home Performance Group Ductwork Installation in Kansas City

If you are building a new home or finishing a basement, make sure your service provider is contracted to both mastic seal and insulate any new ductwork system. If you are experiencing comfort issues in an existing home, duct problems may be the culprit.

At Home Performance Group, we continue to invest in technical training so we can correctly design, fabricate, seal and insulate ductwork. We have performed numerous ductwork installations for our clients. Our in-home consultations are no cost, and with a system purchase include a copy of the duct design. Alternatively, if you choose not to buy from us, we can provide you the ductwork layout and design for a nominal fee.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 12 Jul 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |