Insulated Concrete Form Homes – Healthy Buildings

Although media outlets often headline climate change and outdoor air quality issues, such as smog, we spend most of our lives indoors. A study sponsored by the United States Environmental Protection Agency (EPA), and published in the Journal of Exposure Science & Environmental Epidemiology finds we spend 87% of our time indoors, and another 6% of our time enclosed in vehicles. The air we breathe almost exclusively originates from inside the buildings we live and work. The question is, how healthy are our buildings and the air we breathe?

As building and energy codes demand lower energy consumption, homes will continue to be built ever more air tight. With tighter building envelopes separating us from the outside environment, we must mechanically ventilate our homes correctly, but also the building materials we select become much more important. Many building materials discharge volatile organic compounds, or release particulate matter, into the breathable air. This is particularly acute during the first several years of service. Additionally, various building materials react to changes in temperature or humidity levels which may contribute to product degradation or mold and other organic growth. Insulated concrete forms, once installed, deliver a static building system that do not easily react to temperature and moisture variations, nor suffer from chemical or particulate shedding. These attributes of ICF construction significantly improve the health of a building and the safety of occupants.

ICF Blocks – Environmental and Health Research

Insulated concrete forms are an inert building material that do not react with other chemicals. Additionally, the continuous single concrete core is non-reactive and aids in preventing air leakage through an interstitial wall cavity preventing insulation particles, and other dust or organic matter from mixing into the indoor air. ICF blocks are manufactured mainly with expanded polystyrene (EPS) foam insulation which by itself does not burn, but simply melts when exposed to open flames. A technical paper produced by BASF maintains EPS foam insulation does not contain any ozone depleting substances or formaldehyde, and does not off gas harmful VOCs, shed particulate matter, or release carbon dioxide. Additionally, the stringent European environmental product declaration for EPS insulation affirms, outside of manufacturing, no additional health protection measures are required when working with EPS insulation. The declaration further states EPS foam has been used safely for more than 50 years with no known negative health effects for people or animals, and no adverse impact to the environment. Clearly, when compared to other building materials, such as engineered lumber, veneers, and sheets products, ICF blocks do not contribute to indoor air pollution. The inert quality of insulated concrete form construction makes our buildings healthier, and much safer for occupants.

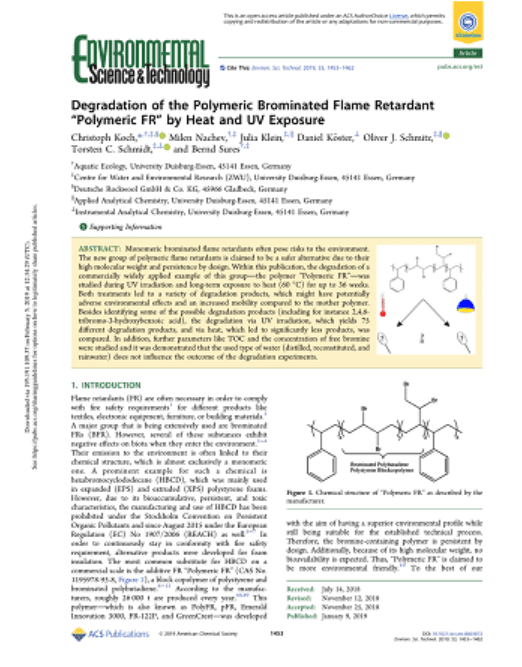

During manufacture, insulated concrete form blocks are treated with a fire retardant (FR) in order to meet safety standards for fire and smoke, specifically ASTM E119. The Fire retardant inhibits the ignition or combustion of plastics rendering the foam thermally stable. As compared to the standard 20-minute fire rating of most wood walls, nearly all ICF products achieve a 4-hour fire rating, providing occupant safety in the event of a wild fire, and increased escape time from fires originating from the inside. Initially, Hexa-Bromo-Cyclo-Dodecane (HBCD) was the preferred fire retardant used with ICF blocks. However, in the early 2000s questions were raised regarding the environmental and potential health effects of HBCD. Although numerous studies found HBCD was not entering the environment in a quantity to constitute a human health risk, the plastics industry worked in conjunction with the EPA to identify potential fire-retardant alternatives. In 2013, industry settled on the use of polymeric fire retardants as the future HBCD replacement. Polymeric flame retardants contain chains of atoms that together create larger molecules than previous flame retardants. The larger size of the molecules renders the compounds safer due to the inability of the chemical to enter organic cells. Finally, In June 2014, the EPA published their final report on flame retardant alternatives for Hexa-Bromo-Cyclo-Dodecane (HBCD). From more than 550 available alternatives, the EPA recommended three polymeric flame retardants (PFR). As compared to HBCD, all three-alternative flame-retardants substantially reduce potential human health effects, toxicity, and environmental impact. However, in 2019, Environmental Science and Technology published a report claiming polymeric flame retardants used in XPS and EPS foam may break down in the presence of high heat or ultraviolet light. Testing found, long-term exposure to sunlight, and temperatures in excess of 140oF, led to some degradation of the PFR coating. Researchers posited the PFR degradation products may pose some potential environmental impacts, although no testing was specifically cited. Since then, further research into PFRs have been conducted. In February 2021, a stability assessment of polymeric flame retardants was completed by the National Center for Biotechnology Information, and published through the United States National Institutes of Health (NIH). The study examined how PFRs may degrade over time under exposure to UV and high heat, similar to the previous testing in 2019. However, scientist looked at application relevant conditions that insulations may experience real-world. In comparison, the 2021 testing evaluated PFRs at 122oF, a more realistic real-world temperature exposure of insulations, versus the 140oF used in the 2019 study. Researchers found negligible degradation of PFR at ambient temperature, and predict it would take at least 100-years to shed even 1% of the PFR. Further, damage from UV exposure resulted in only a minimal loss of Bromine primarily at the surface of the insulation, and small-molecule products were found to be biodegradable, and not persistent in the environment.

Again, insulated concrete form construction was found to be both environmentally responsible, and healthier for occupants. When compared to many other building materials such as engineered wood and sheathing products using various adhesives, glues, and additives, ICFs are a much safer alternative and do not contribute to indoor air pollution.

Insulated Concrete Forms – Green Building Certifications

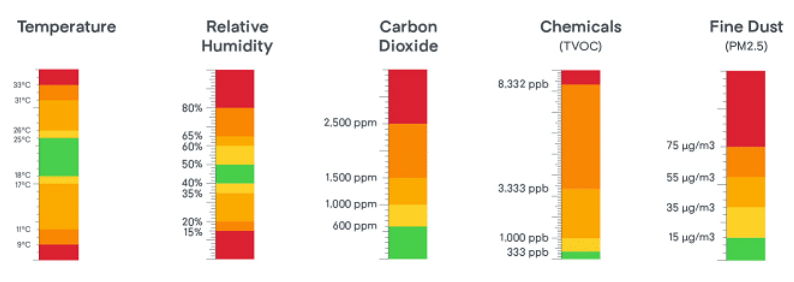

Another, more widely used, green building certification is the United States Green Building Councils (USGBC), Leadership in Energy and Environmental Design (LEED) program. The program is focused both on environmental impact and healthy outcomes for homebuyers. The certification holistically assesses a building across several elements such as energy use, water use, material selections, and overall building health. The aim of the program is to deliver buildings that significantly reduce energy and water use, lower carbon emission, and create healthier environments as measured by reduced VOC, PM, carbon dioxide, and better controlled temperature and humidity. The LEED program offers four levels of building certification with a total of 110 possible points. The incorporation of insulated concrete forms may, by themselves, net as much as 40 qualifying points achieving LEED “certified” status for the project as a whole. Small enhancements in mechanical, electrical, and plumbing systems may easily attain silver, gold or platinum project certification.

Due to the inert and stable nature of ICF materials, coupled with homebuyers focus on healthy homes, insulated concrete form construction now accounts for nearly 20% of new home building in North America. The products red list approved status, coupled with supporting scientific research over the previous two decades confirms the human health and environmental benefits of ICF construction. The acceptance of insulated concrete form technology into both of the leading green building certification programs further demonstrates the environmental, safety, and energy advantages of choosing an ICF built home.

Home Performance ICF Construction in Kansas City

Considering building a new home, shop, or out-building? Interested in a storm resilient structure? Looking for a long-term high-performing structure? Consider hiring a full-service construction firm specializing in insulated concrete form building. Careful selection of an experienced ICF builder can offer decades of safe, comfortable, low-cost living.

At Home Performance Group, we continue to invest in technical training so we can correctly design, specify, size, and install ICF foundation and wall systems. We have performed numerous insulated concrete form projects for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 30 March 2023

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |