Insulated Concrete Form Construction – Conserving Energy and Carbon

Insulated concrete form construction can conserve energy as well as carbon. In the United States, buildings and homes account for 76% of electricity use and 40% of all energy consumption. As fossil fuel use is reduced either through government actions, or market activity, the cost of natural gas and propane will certainly continue to increase. In the case of electricity, the United States Department of Energy, Office of Scientific and Technical Information, summarized expected impacts on grid operators from electrification of transportation and building conditioning. As more electric vehicles (EVs) are brought online to replace internal combustion engines (ICE), and home heating and cooling systems transition from gas to heat pump technologies, electricity demand will rise correspondingly.

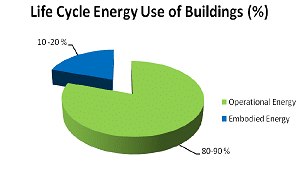

For homes, the two primary energy drivers are embodied energy and operating energy. Operational energy is the energy, usually electricity and/or gas, to run a home or building. Examples include heating, cooling, dehumidification, ventilation, water heating, lighting, cooking, and appliance use. Operational energy is paid for monthly in the form of utility bills. Embodied energy on the other hand is the total energy used to produce building materials and products to construct a home or facility. Embodied energy accounts for the energy required to mine, manufacture, and transport building products, as well as the actual construction. ICF construction generally requires larger embodied carbon and energy inputs compared to wood frame methods. This is due to the use of concrete and steel, both of which involve large amounts of energy to produce. However, replacement of Portland cement with supplementary cementitious materials (SCM), such as fly ash, have been found to decrease the carbon and energy footprint of concrete by roughly the same percentage of substitution. Therefore, improvements in concrete mixes can significantly reduce embodied energy of ICF construction. The University of Calgary developed a sustainable concrete mix using high volumes of fly ash, between 60 to 70% substitution. Laboratory and real-world field testing have yielded positive results in strength, workability, and reduced carbon. Given that, embodied energy as compared to operating energy, is a small percentage over a home’s lifetime. Research on the relationship between embodied and operational energy found embodied energy generally accounts for 10 to 12% of total energy use in standard built homes. This means most energy and carbon reductions are harvested from reducing the utility bills over a building’s useful lifetime.

The most common method to investigate embodied and operational energy is the life cycle analysis (LCA) approach. A study at the University of Tennessee compared energy intensity differences between light framed wood construction techniques, and insulated concrete form methods. Taking into account both embodied energy for new construction, and operating energy over the expected lifetime of a structure, insulated concrete form walls use 14% less energy than traditional wood framed walls and reduce greenhouse gas (GHG) emissions by as much as 12%. A Florida Solar Energy Center (FSEC) field test confirmed ICF homes use 17 to 19% less energy for cooling compared to standard wood framed homes in southern climate zones.

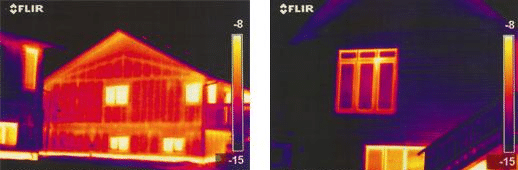

Insulated concrete form wall and foundation systems effectively reduce the energy footprint of a home through energy conservation measures. Specifically, reducing heat transfer into the home in the summer, and heat loss out of the structure during the winter. The United States Department of Energy (DOE) estimates 42% of the operational energy used in homes and buildings is used for space conditioning, while the EIA has found heating and cooling account for as much as 54% of the energy required to operate a home. By reducing heat movement into and out of a home, the amount of air that requires conditioning decreases. This puts a smaller loads on heating and cooling equipment, requiring systems to run less, at lower loads, thereby significantly decreasing overall energy use. ICF wall systems achieve such impressive results through three specific functions. Continuous insulation that eliminates thermal bridging, improved air tightness reducing uncontrolled air infiltration, and thermal mass which provides a dampening effect.

ICF Walls Eliminate Thermal Bridging and Offer Higher R Values

Continuous insulation, meaning unbroken insulation, eliminates thermal bridging problems associated with traditional wood and steel framed walls with cavity insulation.

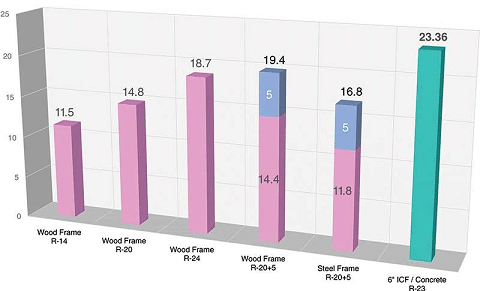

The effective R value of a standard code-built wood wall with R-20 cavity insulation is approximatley R-14.8,

Insulated concrete form construction eliminates thermal bridging and the associated risks. Additionally, ICF construction offers significantly higher effective insulative values than wood or steel frame construction methods. Today, some ICF manufacturers offer insulated concrete form systems reaching insulative R values as high as R-35, delivering as much as 90% more insulation and thermal control than standard wood-frame wall systems without the risk for moisture and rot problems.

ICF Walls Increase Air Tightness and Offer More Comfort

Improved air tightness reduces uncontrolled air infiltration through joints, cracks, and holes through exterior walls, ceilings and floors. The most common locations for air infiltration are joints between sheathing, and cracks around doors, windows, exterior receptacles, hose bibs, and vent pipes. During the summer season, hot humid air can leak into a home generating hot spots inside the building, while adding large quantities of unwanted moisture. During winter months, warm inside air will leak out to the exterior creating cold rooms and dry air. Both scenarios result in challenges with comfort and may dramatically increase the amount of heating, cooling, and dehumidification that must be paid for.

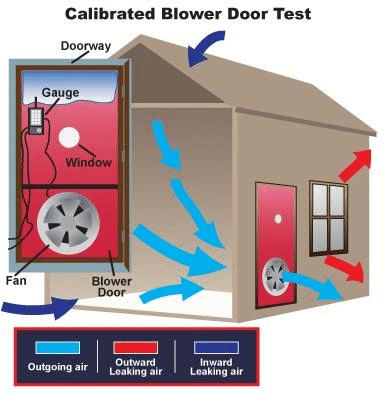

Air tightness is measured through a blower door test. Air tightness testing may be performed as a standalone assessment, or more commonly as part of a larger whole home energy audit in conjunction with thermography.

Insulated concrete form construction significantly decreases the amount of uncontrolled air movement into and out of a home. ICFs achieve better air tightness due to the monolithic concrete core sandwiched between the insulation layers. The concrete serves as a continuous air barrier eliminating air leakage common between wood sheathing joints and sills. Work done by RDH building science, in conjunction with research by Oak Ridge National Laboratory (ORNL), and Massachusetts Institute of Technology (MIT), found the average air leakage rate for wood framed homes was 4.8 ACH50, while insulated concrete form construction averaged just 1.26, during the same time period. Therefore, insulated concrete form construction yielded a nearly 75% reduction in uncontrolled air leakage compared to code-built wood framed homes. Today, many ICF built homes are meeting and beating the passive house air leakage standard resulting in corresponding improvements in occupant comfort, health, and lower energy use reflected in owners’ utility bills.

ICF Wall Thermal Mass Offers More Safety & Peace of Mind

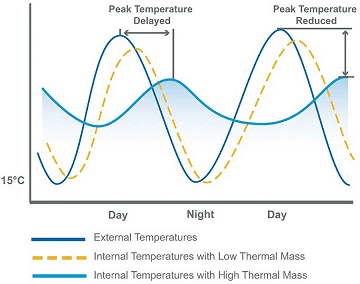

Thermal mass refers to the ability of a material to absorb and store heat. According to the United States Census Bureau, most new residential construction in the United States is light wood framed construction. Wood frame construction provides little in the way of thermal mass to a building.

Finally, the thermal capacity of concrete, coupled with insulation lag time, allows occupants to safely shelter in place for longer periods of time during power outages. climate related events which render utility services non-operational.

Taken together, continuous insulation, superior air tightness, and thermal mass combine to deliver a better wall assembly, extraordinary comfort, and significantly lower utility costs.

Home Performance ICF Construction in Kansas City

Considering building a new home, shop, or out-building? Interested in a storm resilient structure? Looking for a long-term high-performing structure? Consider hiring a full-service construction firm specializing in insulated concrete form building. Careful selection of an experienced ICF builder can offer decades of safe, comfortable, low-cost living.

At Home Performance Group, we continue to invest in technical training so we can correctly design, specify, size, and install ICF foundation and wall systems. We have performed numerous insulated concrete form projects for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 21 June 2023

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |