Properly Design And Size Ductwork To Maximize Comfort And Improve Building Health

The critical role of ductwork in a heating and cooling systems is routinely ignored or simply not understood. Even when an air-conditioner and furnace are properly sized, a deficient ductwork system will adversely affect heating and cooling performance, owners’ comfort, building and occupant health, and operating costs.

Our Director of Training Explains:

Often, poor heating and cooling performance is attributed to the air-conditioner and/or furnace, when the actual problem is undersized ductwork, improper layout or poor workmanship.

Often, poor heating and cooling performance is attributed to the air-conditioner and/or furnace, when the actual problem is undersized ductwork, improper layout or poor workmanship.

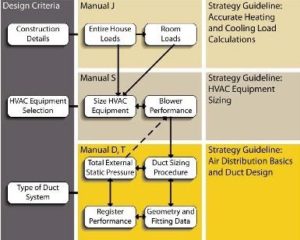

The only method to correctly determine duct layout and calculate trunk, supply and return sizes is to complete an ACCA (Air-Conditioning Contractors of America) compliant Manual D design. In fact, current building codes, specifically 2018 IRC (International Residential Code) section M1601.1, require duct analysis and design according to the Manual D procedure. The codes further specify installation requirements, specifically, 2018 IECC (International Energy Conservation Code) section R403.3, requires ductwork both to be sealed and insulated which is reiterated in IRC section M1601.4.6 and ACCA Manual D A10-5.

Benefits of a Completing a Manual D or Correcting Duct Deficiencies

- Improved temperature control year-round. The delivery of optimized airflow and even air distribution in each room or zone offers equal temperatures throughout the home, particularly during extreme weather events such as the heat of summer and the cold of winter.

- Enhanced moisture regulation and comfort within the home. The ability of a heating and cooling system to maintain consistent indoor relative humidity within a safe and comfortable zone is determined by numerous factors. A duct system designed to minimize air friction, resistance and pressure drop within the ductwork, through the indoor fan motor, and across the evaporator coil enables the heating and cooling system to properly regulate moisture in the air.

- Healthier home to live and work. Infectious bacteria and viruses thrive in humidity extremes. Bacteria, mold, and allergenic mites and fungi thrive in high humidity environments, while viruses prefer low indoor air moisture to stay suspended longer. Maintaining indoor humidity between forty and sixty percent reduces many adverse health effects. Good ductwork design and sizing ensure proper airflow, velocity, mixing and delivery to keep relative humidity at the optimum level.

- Reduced operating costs and monthly utilities. Typical duct systems lose 25 to 40 percent of the heat or cooling produced by the furnace or air-conditioner. These losses manifest in two ways, 1) heat loss or gain through conduction due to a lack of duct insulation and 2) air leakage through unsealed joints and connections. Appropriate duct layout, correct sizing, joint sealing, and insulation can achieve a 50% reduction in energy losses resulting in considerable annual savings.

Ductwork System Design

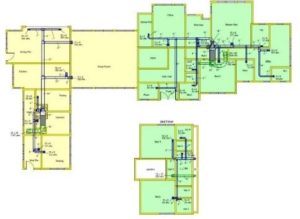

As air moves through any type of duct, the sides and surfaces create friction and resistance to airflow. The layout of the duct system, particularly the total length of the duct more specifically the longest run, type of fittings, connectors, and air supply and return grilles and registers all contribute to, and affect the amount of friction within an air distribution system. Given a proposed duct system, as the volume (CFM) of airflow increases within the trunk and branches, the amount of resistance increases. Therefore, the size and type of heating and cooling equipment selected through the Manual S procedure as determined by the Manual J load calculation must be considered when sizing the ductwork. As the equipment size and therefore the indoor fan motor CFM increases, ductwork must correspondingly increase in size to keep airflow friction within a manageable range, and ensure proper airflow across the air-conditioner evaporator coil.

Designing a new ductwork system or assessing existing requires careful attention to detail, skill and training.

Home Performance Group Heating and Cooling Services in Kansas City

If you are building a new home or finishing a basement or space, make sure your contractor is trained and experienced in performing Manual D ductwork design. Be prepared if they ask you to pay for it: Manual D analysis and design is time-intensive and requires several hours or more to properly complete all necessary steps, calculation and analysis.

At Home Performance Group, we continue to invest in technical training and up-to-date software so that we can correctly layout and accurately size our customer ductwork systems. We have performed numerous designs for our clients and prospective clients. Our in-home consultations are no cost and include a copy of the duct design with a system purchase. Alternatively, if you choose not to buy from us, we can provide you the ductwork layout and design for a nominal fee.

If you are interested in a no cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 21 June 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |