Sewer Pipe Replacement | Is My Sewer Pipe Lateral Functioning Properly?

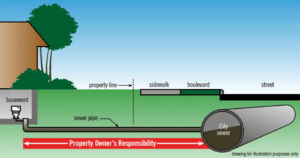

Sewer pipe replacement can be imminent when experiencing sewer clogs and backups. A critical component to home sanitation and good health is a proper functioning sewer system. There are more than 500,000 miles of private sewer laterals in the United States. A sewer lateral consists of the plumbing pipe that connects home drains to the public  sewer mains. Sewer laterals run through private property generally under yards, driveways and patios while public mains are almost always under the street. Most homeowners do not realize they own the sewer lateral, and therefore are responsible for maintenance and repairs. When a home’s sewer lateral fails, the result is generally sewer overflows inside the home. Raw sewage poses considerable health concerns for occupants.

sewer mains. Sewer laterals run through private property generally under yards, driveways and patios while public mains are almost always under the street. Most homeowners do not realize they own the sewer lateral, and therefore are responsible for maintenance and repairs. When a home’s sewer lateral fails, the result is generally sewer overflows inside the home. Raw sewage poses considerable health concerns for occupants.  Additionally, when sewer laterals develop cracks or collapse, sewage may seep out into the surrounding soil, groundwater, and streams, raising contaminant levels particularly E-coli. In some instances, the opposite may occur where groundwater or rain runoff infiltrate the broken sewer pipe backing up into the home and flooding the public sewer main. Experts estimate that as much as 80% of sewer flooding occurs because of home sewer lateral failures.

Additionally, when sewer laterals develop cracks or collapse, sewage may seep out into the surrounding soil, groundwater, and streams, raising contaminant levels particularly E-coli. In some instances, the opposite may occur where groundwater or rain runoff infiltrate the broken sewer pipe backing up into the home and flooding the public sewer main. Experts estimate that as much as 80% of sewer flooding occurs because of home sewer lateral failures.

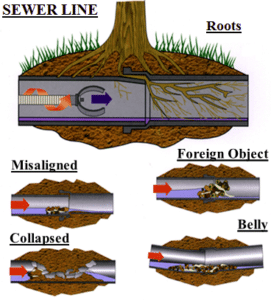

Common Causes of Sewer Pipe Failure

Older sewer laterals were commonly constructed of cast iron or clay piping. According to a study performed by USU (Utah State University), more than 82% of CI (Cast Iron) piping in the United States is over 50 years old and in need of repair or replacement, having reached the end of useful service life. The same study discovered pipe break rates have increased 27% over a six-year period from 2012 to 2018. Even more alarming is break rates specific to cast iron pipe. CI breaks have increased more than 40% over the same time period. The ASCE (American Society of Civil Engineers) assesses the U.S. wastewater infrastructure as a “D”, and a AWWA (American Water Works Association) study determined wastewater pipe replacement continues to be inadequate given the percentage of underground pipe exceeding its useful life.

The five most common causes of sewer pipe failures include:

- Overtaxing the home sewer system. Generally, this occurs due to lifestyle and living habits, and is the most difficult to diagnose and recommend remedy. For example, overloading kitchen garbage disposals, using certain bathing oils, and washing long hair or heavily shedding pets at home. Each activity places excessive strain on the system’s ability to safely convey waste from the home.

- Misuse of the drain system. The IPC (International Plumbing Code), specifically section 302.1, prohibits disposal of dangerous or detrimental materials into the sewer system. The intent is to protect the home’s sewer lateral from clogging and to protect the public utility piping from premature degradation. Some of the most common residential violations include FOG (Fats, Oils, Grease) and other insoluble materials such as sanitary napkins or cotton swags. Those types of materials are especially detrimental with the use of low flow water supply fixtures or ultra-efficient toilets. The primary issue occurs when FOG begins to cool off as it travels through the underground piping. The cooling effect begins to thicken and eventually solidify the oil and grease to the inside walls of the sewer lateral resulting in solid materials becoming lodged resulting in pipe clogs. Sanitary napkins, even those marketed as sewer safe, pose a risk of becoming caught on any imperfection in the interior walls of pipe, or solidified FOG that may have been previously placed into the home drains.

- Breakage or collapse of the sewer lateral. Most breaks and collapse are a result of corrosion or degradation of the pipe materials. Both cast iron and clay pipes are subject to corrosion. Soil composition and chemical make-up often creates a corrosive environment accelerating breakdown. According to the U.S. Department of Agriculture Soil Survey Geographic Database, the Kansas City region has a high corrosive soil potential. Corrosive soil contributes to galvanic corrosion of cast iron sewer laterals and degradation of thin wall clay pipes.

- Infiltration of tree roots into the building sewer lateral. The III (Insurance Information Institute) cites tree roots as one key cause of sewer backups. As trees and shrubs mature their roots naturally grow deeper while seeking moisture. Small ends of roots find water inside sewer laterals through failed pipe joints of old pipe materials. This is particularly common with old clay pipes and cast iron. Over time, due to settling or erosion, the pipes may shift opening a joint connection. Clay pipes are notoriously brittle and may develop cracks while cast iron corrodes and rots from the inside creating holes. Any opening in the sewer lateral invites the infiltration and growth of tree roots into the sewer piping system eventually leading to clogs and backups.

- Venting problems of the drain system. An often-overlooked issue are blocked sewer vents. Proper airflow, or more precisely pressure, must be maintained throughout the plumbing drain system to protect water sealed traps, prevent sewer gas infiltrating into the home, and ensure waste is efficiently carried away through the sewer lateral. Symptoms of venting problems include gurgling sounds or bubbling up of waste water in the homes drains and toilets.

Need for Sewer Pipe Replacement?

Three less common, but equally serious sewer lateral failures:

- Pipe bellies are dips or slumps which fundamentally change the slope of the pipe. Bellies most often occur from settlement of the soil through erosion, compaction, or some other geological event. When a pipe loses support beneath, the weight of the pipe, waste, and ground above causes the pipe to sag. The depression created in the pipe collects solids, waste, and holds water which leads to clogs and sewer back-ups.

- Pipe channeling differs from pipe bellies in that the overall pipe slope does not change. The top of the pipe may still have a downward slope away from the home to the public sewer main, however, the bottom of the pipe erodes away or otherwise deteriorates. This creates a low spot in the pipe that collects both water and solids, while creating openings for root infiltration.

- Improper installation of pipes and/or fittings. Contractors failing to place the sewer lateral on an undisturbed non-expansive base, or compact the pipe trench bottom, run the risk of eventually losing slope in the sewer pipe. Additionally, over time pipe bellies may develop through soil erosion or compaction. In either case, the slope of the pipe is changed resulting in problems with waste conveyance.

Replace Cast Iron and Clay Sewer Pipes with PVC Plumbing

PVC piping has the lowest failure rate among the various types of sewer pipe materials. Additionally, PVC provides both rigidity to maintain a constant slope, and some flexibility to adjust to changes in the soil. Clay pipes are inherently brittle and simply crack, or pull apart from joints under little load. Unlike ferrous cast iron metal piping, PVC does not corrode, rust or otherwise break down. Therefore, the installation of PVC piping eliminates a significant contributing factor experienced in cast iron degradation, namely corrosion caused failure. The USU study referenced earlier found 75% of all utilities operate underground piping in one or more areas with corrosive soil conditions. Property owner’s private sewer laterals connected to those utilities are also found in the same unforgiving soil. When exposed to harsh soil conditions cast iron breaks down much quicker and experiences 20 times more pipe breaks. A final contributing factor to cast iron failures is the thickness of pipe walls. Post-World War II cast iron pipes were manufactured with thinner walls resulting in faster development of holes, cracks and breaks. Couple poor soil conditions with thinner wall piping and one can see why old cast-iron sewer laterals fail at such a high rate.

Home Performance Group Sewer Pipe Replacement in Kansas City

Do you experience frequent clogs, or sewer back-ups? Concerned your sewer lateral may need replacement? Consider hiring a full-service plumbing professional with specialized knowledge to properly install your new sewer lateral. Our experts are available for helping you to make the right decision for optimum value.

At Home Performance Group, we continue to invest in technical plumbing training so we can correctly design, specify, size, and install plumbing systems, sewer laterals, and septic systems. Our highly trained staff have performed numerous projects for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 4 October 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |