What Is a Ground-Fault Circuit Interrupter?

Background and Development of GFCI Protection

Beginning in earnest in the 1920s and continuing through the 1950s an explosion of electric household appliances were invented, marketed, and sold in the United States. These appliances were built on metal frames and chassis and connected through two-wire electrical circuits. This configuration created a dangerous scenario where in the event an appliance suffered an internal electrical fault, the appliance housing could become electrified and present a touch hazard to users. The results were more than 1,000 household deaths per year with nearly half caused by consumer appliances.

Beginning in 1956, the NEC began requiring the addition of an equipment grounding conductor (EGC) installed with the ungrounded “hot” conductor, and the grounded “neutral” conductors. The EGC is an electrical safety system and is identified as the bare copper wire connected to the appliance’s chassis or frame. The wire provides a low resistance path back to the main electrical panel. In the event the appliance suffers an internal electrical failure in which the ungrounded hot wire touches the frame, the EGC directs power back to the panel forcing the circuit breaker to trip, preventing electric shock hazard or potentially life-threatening electrocution.

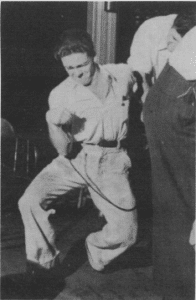

After implementation of the EGC requirement real academic interest and study began on electrical shock hazards. Professor Charles Dalziel served in the Electrical Engineering and Computer Science department at the University of California Berkeley from 1932 to 1967. Additionally, he worked with General Electric, and served on the National Defense Research Committee. His research centered around electric shock, heart fibrillation, and physiological damage caused by electricity. Experiments on men and women carried out in the early 1960s led to the development of safety thresholds and maximum let-go standards to prevent life threatening electrocution and significant injury. In 1965 Professor Dalziel filed for and received a patent for the ground-fault circuit interrupter.

How Does a Ground Fault Circuit Interrupter Work?

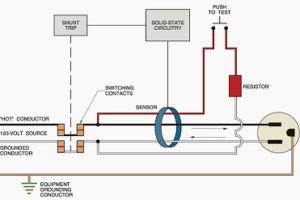

A GFCI monitors electrical current in both the grounded conductor, commonly referred to as the neutral, and the ungrounded conductor generally referred to as the hot.

There are two types of ground-faults. A type one fault is caused when the ungrounded conductor comes in contact with an appliance or device chassis that is properly grounded. The low resistance EGC directs the current flow back to the panel causing an intentional massive current spike that forces the circuit breaker to trip. Generally, most standard circuit breakers detect and react to such faults. In contrast, a type two fault occurs after the electricity has travelled through the appliance load or occurs because of a National Electric Code violation. A type two fault is a high resistance event that standard circuit breakers do not detect and therefore cannot provide protection against. A type two ground fault is still very dangerous and can be lethal particularly when involved around water. A common code violation that can create a type two ground-fault is a bootleg ground condition. Often a wire is placed to connect the grounded “neutral” conductor or terminal to the device or appliance chassis and the EGC. During such a wiring configuration, anytime the 120-volt circuit is energized the chassis or frame is electrified as well. Ground-fault circuit interrupters are specifically suited to detect such wiring issues or high resistance ground faults.

Does My Home Have Adequate GFCI Protection?

Existing homes built prior to 1971, were not equipped with ground-fault circuit interrupters at the time of construction. The Electrical Safety Foundation International (ESFi) estimates there are more than 43 million American homes lacking adequate protection. Most Authorities Having Jurisdiction (AHJ) do not require homes to upgrade to current codes unless the system is materially changed, renovated or repaired. Therefore, older homes without significant renovations or repairs to electrical circuits may not offer occupants any electrical ground-fault protection. Additionally, electrical codes are revised every three years. Since 1968, GFCI protection has been expanded numerous times meaning although an older home may have some ground fault protection receptacles, the home may still lack complete protection in all necessary rooms. Finally, the presence of a GFCI device whether a receptacle or circuit breaker does not mean there is any ground-fault protection. Research by the U.S. Consumer Product Safety Commission (CPSC) and National Electrical Manufacturers Association (NEMA) found between 8 and 14% of ground-fault circuit interrupters fail to operate properly. Common causes include damage from electrical surges in high lightning regions, and corrosion due to moisture in high humid areas. The report concluded annual testing should be part of a whole home preventive maintenance program.

Home Performance Group GFCI Installation in Kansas City

Need or simply want ground-fault protection in your home? Not sure you have GFCIs in the correct rooms or spaces? Consider hiring a full-service electrical expert with specialized knowledge to properly inspect, recommend, and install ground-fault protection in your home. A small upfront investment in careful contractor selection can protect the people that mean the most to you, your family.

At Home Performance Group, we continue to invest in technical electrical training so our team can correctly diagnose, inspect, specify, and install ground fault protection and systems. We have performed numerous professional installation jobs for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 8 November 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |