What is The Purpose of a Septic Tank?

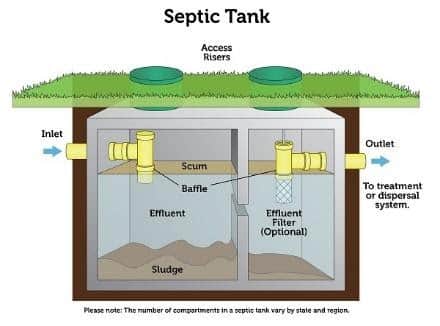

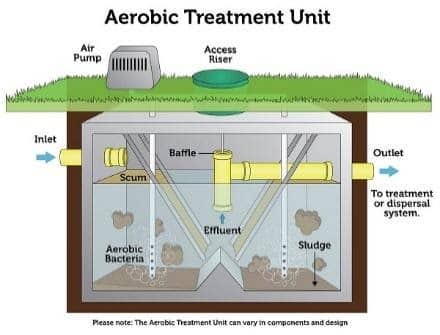

The question periodically arises, what is the purpose of a septic tank and do I really need one? To answer that question, we must first understand the essential function of an onsite wastewater treatment system (OWTS). All waste water must be treated to render effluent safe from disease causing pathogens such as bacteria, viruses, intestinal worms, and protozoa. Treatment is performed in multiple sequential steps, each with a specific goal. Once waste water leaves the home,  the first step, pretreatment, happens in a tank, which may be either a standard septic tank, or alternatively an aerobic treatment unit (ATU), more on that later. The tank is an underground watertight compartment constructed of concrete, fiberglass, or high-density polyethylene. Both standard septic tanks and ATUs are separated into a minimum of two internal compartments to provide primary treatment of the wastewater through separation of solids. The first chamber allows untreated wastewater to collect where heavy solids sink to the bottom and other solids float to the top. This separation is critical for long term system performance because the process significantly reduces the solids loading rate in downstream wastewater treatment components. The layer at the bottom of the tank is managed through bacterial digestion which is why septic tanks generally only require pumping every three years. The water between the two layers is known as the clear zone and provides highly clarified effluent that moves into the next tank chamber through an internal baffle.

the first step, pretreatment, happens in a tank, which may be either a standard septic tank, or alternatively an aerobic treatment unit (ATU), more on that later. The tank is an underground watertight compartment constructed of concrete, fiberglass, or high-density polyethylene. Both standard septic tanks and ATUs are separated into a minimum of two internal compartments to provide primary treatment of the wastewater through separation of solids. The first chamber allows untreated wastewater to collect where heavy solids sink to the bottom and other solids float to the top. This separation is critical for long term system performance because the process significantly reduces the solids loading rate in downstream wastewater treatment components. The layer at the bottom of the tank is managed through bacterial digestion which is why septic tanks generally only require pumping every three years. The water between the two layers is known as the clear zone and provides highly clarified effluent that moves into the next tank chamber through an internal baffle.

Importance of Proper Septic Tank Sizing

Septic tank sizing is critically important to long-term reliable operations of a private onsite wastewater treatment system. Done correctly, tank sizing requires time and follows a specific mathematical methodology to calculate the proper storage capacity in order to retain wastewater in a quiescent environment. Sizing assesses the homes expected daily flow rate based on the number of bedrooms in a home. Done incorrectly, septic system performance will suffer. By not providing correct treatment of the waste water will result in potentially catastrophic failure due to clogs, and absorption field failure.

The pretreatment separation and settling process requires two to four days to complete. The time wastewater remains inside the septic tank is known as retention time. The larger the tank volume, the more retention time for primary treatment, therefore when sizing a septic tank or ATU, the tank must possess a capacity large enough to store a minimum of two days of household waste water and have adequate space to provide a turbulent free environment. Undersized tanks will not provide enough retention time for separation and settling of solids, and excessive flow rates can disrupt the pretreatment process.

Sizing a tank begins with understanding the expected daily flow rate of the home. Designers look at the average amount of wastewater produced per person. Actual rates range from 30 to 65 gallons per person per day. Homes equipped with low flow fixtures and toilets tend to operate at the low end of the range. A common planning factor endorsed by most Authority Having Jurisdiction (AHJs) is 60 gallons per person per day. Predicting the actual number of people that may occupy a home is impractical for a variety of reasons, therefore the majority of AHJs base sizing calculations on potential occupancy for residences. This is done by counting the number of bedrooms in a home. State or AHJ septic systems construction guidelines provide tables specifying tank sizes based on the number of bedrooms. Homes larger than 5 bedrooms require a manual calculation.

What is the Difference Between a Septic Tank and ATU?

The core difference between tanks relates to treatment, specifically how wastewater is processed by different types of microbes. Standard septic tanks maintain an anaerobic environment effectively devoid of free oxygen, particularly within the liquid effluent. This kind of treatment is generally slow, and inefficient, producing foul gas and acids as sludge is digested and processed. Anaerobic treatment generally reduces Biochemical Oxygen Demand (BOD), and Total Suspended Solids (TSS) by about 40 percent but does little to remove excessive nitrogen or phosphorus. The main advantage of a standard septic tank is reliability and low maintenance. Because standard septic tanks have no moving parts, electrical requirements, pumps or motors, there are fewer potential points of failure or breakdown. The entire system is passive and uses gravity only.

Aerobic treatment units,

Factors Affecting Septic Tank or ATU Performance

The microbial digestion and treatment process can be disrupted by changes in temperature and the introduction of adverse substances into the treatment environment. During colder months as internal tank temperatures fall, biological activity and therefore wastewater treatment slow down which may contribute to the accumulation of more sludge at the bottom of the tank. The introduction of fats, oils, and grease (FOG) pose a significant risk to septic tanks and ATUs. As FOG cools it will begin to solidify creating solids or gelatin that accumulate both in the clarified effluent as elevated TSS or at the sludge layer at the bottom of the tank. It is important to pump the tank often, and when pumping, remove as much FOG from the tank as possible. If not, gelatin fats, oils, and grease may travel to the absorption field clogging laterals resulting in costly repairs. Finally, the use of certain household cleaners will also inhibit wastewater treatment, specifically drain cleaners, paints, and other acidic or highly alkaline chemicals which may change the pH of the effluent. The microbes used for biological treatment of wastewater can be easily killed due to sudden shifts, or elevated levels of pH either direction.

There are some simple best practices that will protect septic tank or ATU performance and ensure long-term reliable operation. First, do not install or use a garbage disposal in homes with private onsite wastewater treatment systems. This prevents the introduction of additional solid matter and potentially fats, oils, and grease into the system. Additionally, refrain from flushing chemicals and pharmaceuticals through the drain system. This ensures minimum impact to the pH and chemical composition of wastewater. Finally, ensure annual maintenance is conducted on the septic system to include professional assessment of the sludge and scum layers inside the tank. When required, pump the tank accordingly.

Home Performance Group Septic Tank & ATU Installation in Kansas City

All onsite wastewater treatment systems require a tank for pretreatment. This may be a standard septic tank or alternatively an aeration treatment unit. Need to install a septic tank or upgrade your system to an ATU? Consider hiring a licensed professional with specialized knowledge to properly design, size and install your septic tank or aeration treatment unit. A small upfront investment in careful design can save both the headache of inconvenience and tens of thousands of dollars in future rework.

At Home Performance Group we are both basic and advanced state licensed in septic systems. We continue to invest in technical training so we can correctly design, specify, size and install septic tanks, septic laterals, low pressure systems, lagoons, high-pressure drip systems and complete septic tank service. We have performed numerous septic projects for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 6 December 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |