Why Does Ductwork Make Noise?

One of the most common homeowner complaints is excessive noise and loud sounds coming from ductwork. Most often the noise is noticed when the heating and cooling system cycles on or off. A lack of sound inside ductwork is a characteristic of comfort driven by human perception. A paper by the University of Washington found health and safety issues associated with excessive acoustics. Occupants in a noisy space can suffer from vocal strain, poor concentration, and fatigue resulting in long-term health effects. In addition to posing comfort and health concerns, excessive noise may be a symptom of a much larger problem with the heating and cooling system or ductwork.

Causes of Ductwork Noise Problems

Sound is essentially vibrations or waves travelling in the air spherically outward and bouncing or reflecting off of objects in a space. Additionally, low frequency sound can travel vibrationally through solid structures such as wood, plastics, and metal. Ductwork, especially metal ductwork, creates a funnel for sound, capturing noise created by the heating and cooling system fan, or within the ductwork itself due to poor design, installation or workmanship. The duct system connects all parts of the HVAC system transporting noise to all rooms being heated and cooled. Some of the most common causes of nuisance noise include:

- Oversized HVAC equipment. Too often contractors fail to perform an ACCA (Air-Conditioning Contractors of America) Manual J heating and cooling load calculation. The result may be an oversized HVAC system. Bigger systems move larger volumes of air. Too much air flow will result in an increase in the velocity of air, think what happens when you place your thumb over the end of garden hose. This increase speed of air can produce a whistling sound throughout the ducts.

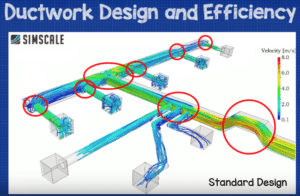

- Undersized Ductwork. If getting contractors to perform Manual J load calculations were hard enough, a Manual D duct sizing calculation is all but non-existent among residential HVAC contractors. Relying on imprecise rules of thumbs, and need to drive cost down, contractors routinely install undersized ductwork systems. Like oversized equipment, inadequate duct sizing creates excessive friction restricting airflow and increasing air velocity. Increased air speed produces a whistling sound through the ductwork system.

- Unbalanced Air Flow. Pressure differences between the air supply and return side of the system can force duct walls to expand and contract resulting in a rumbling or pinging sound. Unbalanced flow may be a design issue in that inadequate return air is supplied to the heating and cooling system, or more commonly, the ductwork on one side of the system is not properly sealed.

- Uninsulated Ductwork. Metal ducts installed in unconditioned spaces such as an attic, basement, or crawlspace can expand and contract due to temperature fluctuations. During the winter, as hot air moves through the otherwise cold ductwork, the metal expands creating a banging or pinging noise, the reverse happens in the summer when cold air is distributed through hot metal duct causing contraction.

- Incorrect Air Supply Outlets. Each register, grille and damper are rated for noise through the NC (Noise Coefficient). The lower the NC number the quieter the outlet given a delivered pressure and velocity of air. Selection of an air supply outlet without regard for the rated NC may result in excessive noise. Special consideration must be given to adjustable air dampers. Closing an air supply damper to much will result in an increase in air velocity causing excessive whistling noise.

- Duct Workmanship. Improperly installed duct components such as separated connections, holes in the duct, or loose parts create edges acting like a reed generating noise. Metal ductwork rubbing against wood framing members, or part of the structure, will result in popping or reverberating sound as the metal duct changes temperature.

- High MERV (Minimum Efficiency Reporting Value) air filters. High-efficient filters generally create much more friction to the movement of air in the form of pressure drop which can starve the indoor fan motor.

Ductwork Noise Solutions and Best Practice

Locating ductwork noise problems is often difficult and can be time consuming. There are two considerations 1) source control of the HVAC equipment or duct defect, and 2) noise path control of the ductwork itself. Sound dampening materials can be installed to block sound waves or to absorb them.

The STC (Sound Transmission Class) of a material indicates the ability of the material to block sound, and generally, the higher the STC rating the more sound is blocked. Like all simplified rating schemes there are nuances to consider. An often-cited problem with the single STC rating is the lack of performance at low frequency, but we will save that for another time. The other rating is NRC (Noise Reduction Coefficient) which measures the quantity of sound absorbed by a material. Most common ductwork materials are NRC rated based on the amount of sound they absorb. NRC is a single decimal number ranging from 0, indicating no sound is absorbed, to 1 meaning all sound striking the material is absorbed.

- Hire a professional to conduct a Manual J heating and cooling load calculation, and Manual D ductwork sizing calculation to ensure the HVAC equipment is sized accurately for the homes load, and the ductwork is not undersized for the equipment.

- Consider mastic sealing and insulating the ductwork system. Sound can travel both through the air and vibrationally through the structure. By sealing ductwork, nuisance noise may be reduced by eliminating an air path into the duct, as well as help to balance supply and return air flows. Sealing both air supply and return ducts ensures air is not lost on one side of the ductwork system, potentially eliminating some pressure balance problems. Insulating the exterior of ductwork helps to isolate and decouple ductwork from the building structure minimizing vibrational noise transmission. Aside from noise problems, sealing and insulating ductwork provides significant health and safety benefits.

- Change existing supply air outlets. Many manufacturers market antique, architectural or otherwise decorative grilles, registers and dampers. Air supply outlets must be selected based on a number of functional characteristics to perform correctly. One of these characteristics is the NC rating of the outlet based on the volume and velocity of air to move through the device.

- For new construction specify to the HVAC contractor, or choose, insulated fiberglass duct board versus uninsulated metal ductwork. Duct board can provide up to nine times more sound control than standard sheet metal duct systems.

- Install a mini-split heat pump which does not use centralized ductwork. A mini-split system delivers heating and cooling to each room or zone through individual air distribution heads connected only by two copper refrigerant lines. Ductless systems deliver comfort, improved sound control, high efficiencies, and less waste.

Home Performance Group Ductwork Installation in Kansas City

If you are building a new home or finishing a basement, make sure your contractor is trained and experienced in performing Manual D ductwork design. Be prepared if they ask you to pay for it: Manual D analysis and design is time-intensive and require several hours or more to properly document all the necessary information and complete the calculation and analysis.

At Home Performance Group, we continue to invest in technical training and up-to-date software so that we can correctly layout and accurately size our customer ductwork systems. We have performed numerous designs for our clients and prospective clients. Our in-home consultations are no cost and include a copy of the duct design with a system purchase. Alternatively, if you choose not to buy from us, we can provide you the ductwork layout and design for a nominal fee.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 26 Jul 2021

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |