Why is High Water Pressure Bad?

Water is an extremely powerful force exerting an enormous amount of energy, particularly when in motion. Water weighs 8.34 pounds per gallon. In a fixed piping system, increasing water pressure increases the velocity or speed of moving water generating an enormous amount of kinetic energy.  Any time water flow changes direction abruptly or stops suddenly the kinetic energy is transferred throughout the plumbing piping, fixtures, and connected appliances. Think of high-water pressure like high blood pressure. Excessive pressure puts unnecessary stress on everything connected to it and accelerates wear and tear. High water pressure can lead to ruptured pipes, failed fittings, and continuous leaks. The Insurance Information Institute (III) found water damage, particularly from leaking piping, accounts for 22 percent of all homeowners insurance claims, with an average claim size of $5,531.

Any time water flow changes direction abruptly or stops suddenly the kinetic energy is transferred throughout the plumbing piping, fixtures, and connected appliances. Think of high-water pressure like high blood pressure. Excessive pressure puts unnecessary stress on everything connected to it and accelerates wear and tear. High water pressure can lead to ruptured pipes, failed fittings, and continuous leaks. The Insurance Information Institute (III) found water damage, particularly from leaking piping, accounts for 22 percent of all homeowners insurance claims, with an average claim size of $5,531.

What is High Water Pressure?

For piping systems inside homes and buildings, the plumbing and building codes prescribe a maximum limit for incoming water pressure. Specifically, the International Residential Code (IRC) section P2903.3.1 states the maximum static water pressure shall not exceed 80 psi. In the event incoming water pressure from the utility is greater than 80 psi, an approved pressure reducing valve must be installed. The International Plumbing Code (IPC), specifically section 604.8, reinforces the IRC 80 psi water pressure limit. The codes also require any pressure-reducing valve to conform to American Society of Sanitary Engineers (ASSE) technical standard 1003.

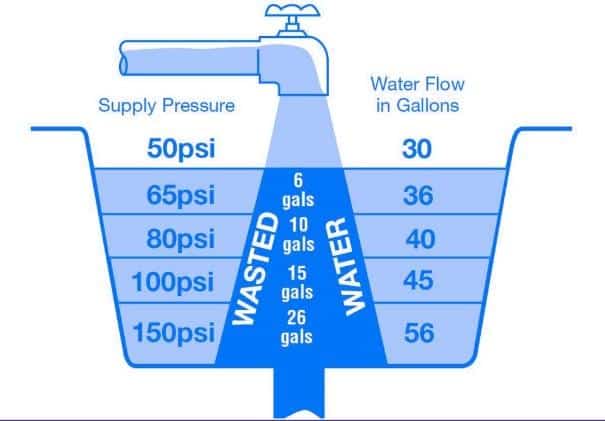

Keep in mind, building codes are the lowest possible standard for safety. Codes are not necessarily good design or offer optimal performance. They provide the minimum floor of performance that all contractors must legally adhere to. That being said, the U.S. Environmental Protection Agency (EPA) has since established an, above code minimum, program for water efficiency. The water sense program is a voluntary building standard for residential and multi-family buildings which aims to encourage construction and purchase of water-efficient homes. Homes seeking this certification must achieve at least 30% better water-efficiency than a typical code-built home. One of the easiest and least expensive ways to achieve water-efficiency is to waste less water. The EPA water sense program calls for a reduction of the incoming static water pressure from 80 psi down to 60 psi. Depending on your goals, the highest water pressure you may want entering your home is 80 pounds per square inch, or alternatively 60 psi offering a more efficient and safer option. Additionally, most pressure reducing valves, once installed, are set between 50 to 60 psi for optimal performance.

Seven Signs You Have Excessively High-Water Pressure

The only way to test for high water pressure is with the use of a water pressure gauge. The best method is to assess both static pressure and dynamic pressure using a single gauge capable of measuring both. Without actual testing, there are some signs that may indicate incoming water pressure is too high.

Water Hammer. Because water is effectively incompressible, a column of water forced to change direction or stop quickly creates hydrostatic shock within the piping. Water hammer can generate a pressure wave up to 60 times the water flow rate in the plumbing system. For example, water traveling at 5 feet per second (fps) may generate 300 pounds per square inch (psi) of pressure. The hammer effect may cause piping to move within the walls and floors smashing into other piping and surrounding structure generating audible banging or clanging sounds. Water hammer can cause more than just annoying noises. If enough force is created water hammer can inflict physical damage to plumbing pipes, fittings, and fixtures and connected appliances.

Leaking Pipe. Most plumbing valves and fittings are designed for a maximum 150 psi of water pressure. When water hammer is generated, high pressure and water velocity can erode plumbing pipes to include metal pipes such as copper and galvanized steel. Often weak joints will develop pinholes, while improperly connected fittings become loose, developing small leaks.

Damaged Appliance. All appliances and mechanical devices have design limits and safe operating ranges. Today, washing machines, dishwashers, and ice makers use rubber or neoprene gaskets to create water tight seals and newer models operate electronic solenoid water valves. Excessive water pressure will eventually rupture watertight seals and damage sensitive electronic water fill valves. Leaking appliances and connections often cause water damage to property and the potential for mold growth.

Leaking Faucets. Like water connected appliances such as dishwashers, washing machines and ice makers, faucets use gaskets of various materials to create watertight valves. Excessive water pressure can deform and misalign the seals preventing the valve from fully closing and seating. This misalignment or obstruction allows water to continuously drip or trickle. Sometimes a faucet may be rebuilt with new gaskets, or seats and springs depending on the make, but high-water pressure will eventually damage the repair.

Running Toilets. In order to minimize cost, most toilet fill valves are built from molded plastics and thin gaskets.

High water pressure, especially over 80 psi, causes extra wear and tear each time the fill valve opens and closes. The extra wear leads to leaking seals on the fill mechanism and a toilet that runs constantly. Toilet fill valves can be replaced, but like the faucet above, without addressing high-water pressure problems, any new fill valve is doomed to the same fate.

Water Heater Damage. Homes with a water heater not equipped with a thermal expansion tank are highly susceptible to damage from high incoming water pressure. A more dangerous situation is a water heater with a pressure relief valve that has corroded close or simply defective. Both scenarios can result in the tank rupturing at a seam or worse yet exploding when going through a heating cycle. Additionally, because high water pressure increases water flow, the hot water heater will become depleted much quicker resulting in running short of hot water.

Environmental Impact. Water is already a scarce resource, particularly in the west and southwest of the United States. Today, in the Midwest region, the vast majority of fresh water provided to our homes originates from lakes and rivers. The U.S Geological Survey (USGS) finds our surface water sources make up less than one hundredth of one percent of the total water on the planet. In a world of accelerated climate change, wasted water from excessive water pressure poses a significant environmental challenge.

Limiting water pressure, minimizes actuation and discharge of pressure relief valves within the plumbing system, reduces water hammer within the piping and corresponding damage, protects water fixtures and appliance valves and mechanisms from excessive pressure exceeding their design limits, and decreases water consumption and unnecessary waste. The best remedy for high water pressure is to install a pressure reducing or regulating valve in the home’s main water supply pipe.

Pressure Regulating Valve Prevents Damage?

A pressure regulator valve (PRV) is simply an adjustable valve that limits the incoming water pressure to a safe level. Building and plumbing codes all require the use of a pressure regulating valve anytime incoming static water pressure exceeds 80 psi.

Anytime a pressure regulator valve is installed, a thermal expansion tank must be installed to protect the plumbing system from excessive water pressure created by the water heater during heating cycles. The plumbing codes, specifically, IPC section 607.3 and UPC section 608.2 require thermal expansion control for storage tank water heaters connected to a plumbing system receiving water passing through a check valve, pressure regulating valve, or backflow preventer. As water is heated, physics dictates the volume of water expands. A PRV acts like a one-way gate and prevents water from flowing back into the water main. Expansion of water caused by the hot water heater results in higher water pressures generated throughout the entire plumbing system unless a thermal expansion tank is installed.

Finally, to prevent potential damage to a pressure regulator valve. Most manufacturers recommend installing a simple check valve or backflow preventer downstream of the PRV. In the event of significant back-pressure created within the home or building, the check valve will close, preventing high pressure from flowing back into the valve potentially causing damage.

Home Performance Group Pressure Regulator Valve Install Kansas City

Concerned you have excessively high-water pressure causing damage? Not sure your PRV is working? Consider hiring a plumbing contractor with the specialized knowledge to assess, specify, and install pressure regulating valves, check valves and thermal expansion tanks. Conscientious selection of a licensed plumbing contractor can protect your property from potential water damage, save thousands of dollars in insurance deductibles and headache.

At Home Performance Group, we continue to invest in advanced plumbing training so we can correctly design, specify, recommend, replace and install pressure regulating valves, thermal expansion controls, and backflow preventers. We have performed numerous projects for our clients.

If you are interested in a no-cost in-home consultation, schedule with a Solutions Advisor today.

Article by Larry L. Motley Jr., 21 February 2022

Larry is a graduate of both Wentworth Military Academy and Missouri Western State University earning a double bachelor’s degree in Economics and Finance. Additionally, he maintains six professional tradesman licenses in two states and advanced credentialing in green technology, project and program management, and process improvement. Larry is a three-time combat veteran having served in Operation Iraqi Freedom, Operation New Dawn, and Operation Inherent Resolve. He continues to serve through a value-based building science company focused on providing clients the best design, highest quality installation, and most honest repair services in the community.

Featured Service Areas:

| Missouri | Kansas | ||||

|---|---|---|---|---|---|

|

Belton Blue Springs Cameron Excelsior Springs Gladstone Holt |

Independence Kansas City Kearney Lathrop Lawson Lee's Summit |

Liberty North Kansas City Parkville Platte City Plattsburg Polo |

Raytown Riverside Smithville Sugar Creek Weston |

Kansas City Lansing Leavenworth Leawood Lenexa |

Merriam Mission Mission Hills Praire Village Shawnee |